Dewert Okin Linear Actuators

Lippert Studios has worked with Dewert Okin for over 15 years on projects ranging from hospital bed actuators to custom control interfaces and linear drive systems. Dewert Okin itself was formed from the merger of two German innovators, Dewert and OKIN, both founded in the 1980s and known for early breakthroughs like the Dymat and OKIMAT actuator lines. Today, Dewert Okin is part of Phoenix Mecano and remains a major leader in medical, bedding, seating and office drive technology.

Delta Drive

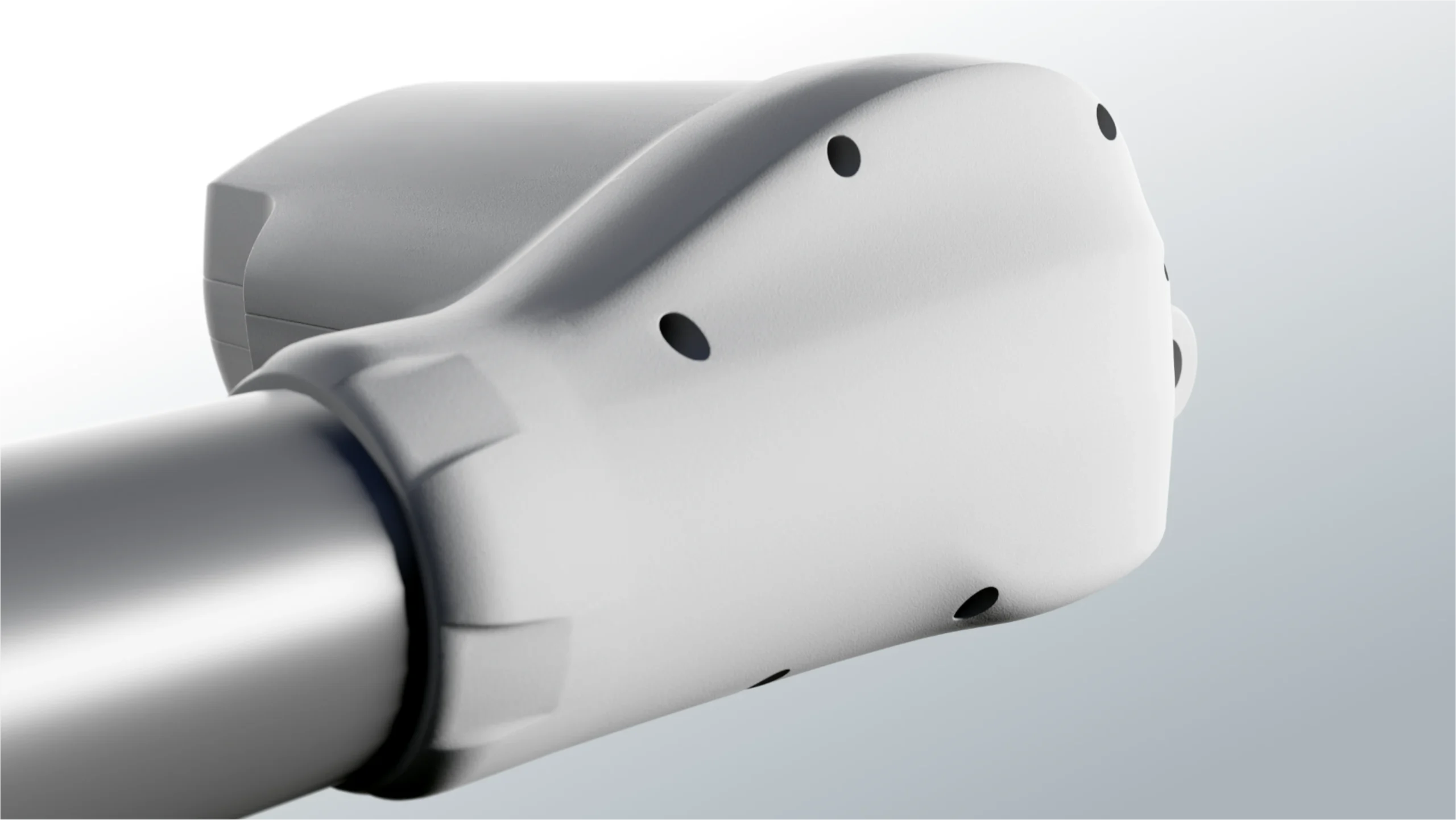

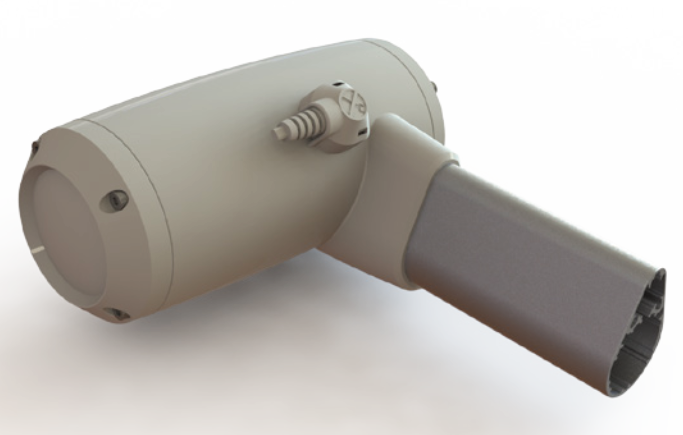

Elegant and minimalistic linear actuation motor system

Final Prototype

The DeltaDrive offers a dynamic, compact design. Thanks to the small number of parts, assembly is significantly easier than with the previous drive. Interchangeable end caps allow the ER or QR functions to be changed which can significantly reduce production costs.

Exploded View

Technical Drawings

Profile orientation A

Profile orientation B

Controls

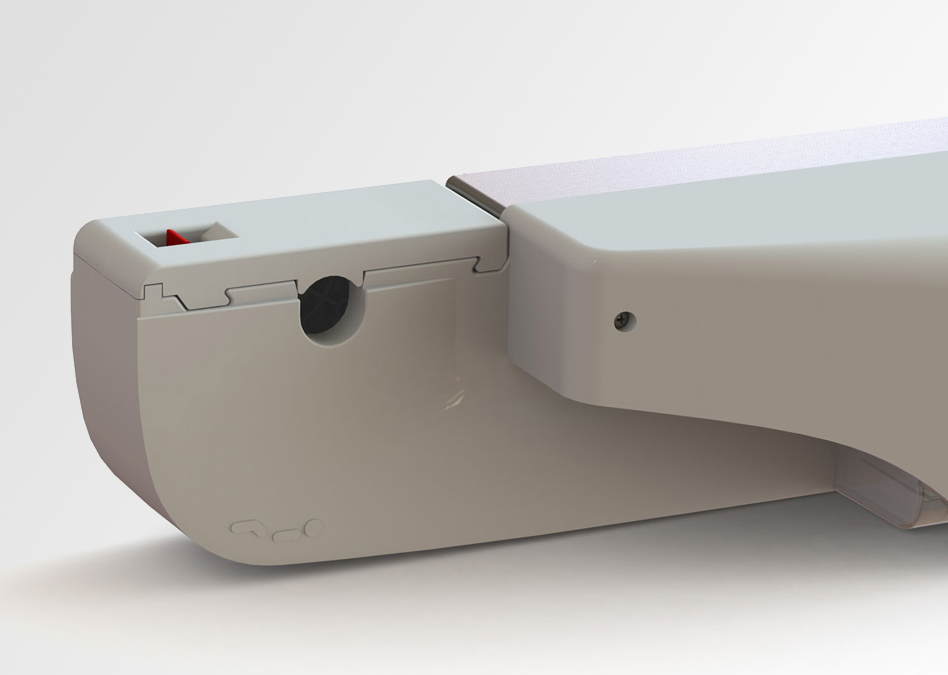

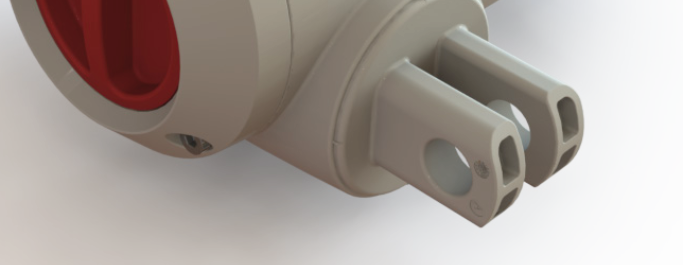

MCL II

The heart of every drive system

Final Prototype

The MCL II is a standalone control component and also offers the option of being connected to the single drive to form a single unit.

Fastening options

Fastening clip

Recesses on the upper and side surfaces of the foam core allow rotation in line with the position of the aluminum profile. By simply changing the foam core, the control can be mounted on different drives with different profiles.

Fastening strap

A flexible strap allows the drive housing and its aluminum profile to be attached to the control housing using Velcro.

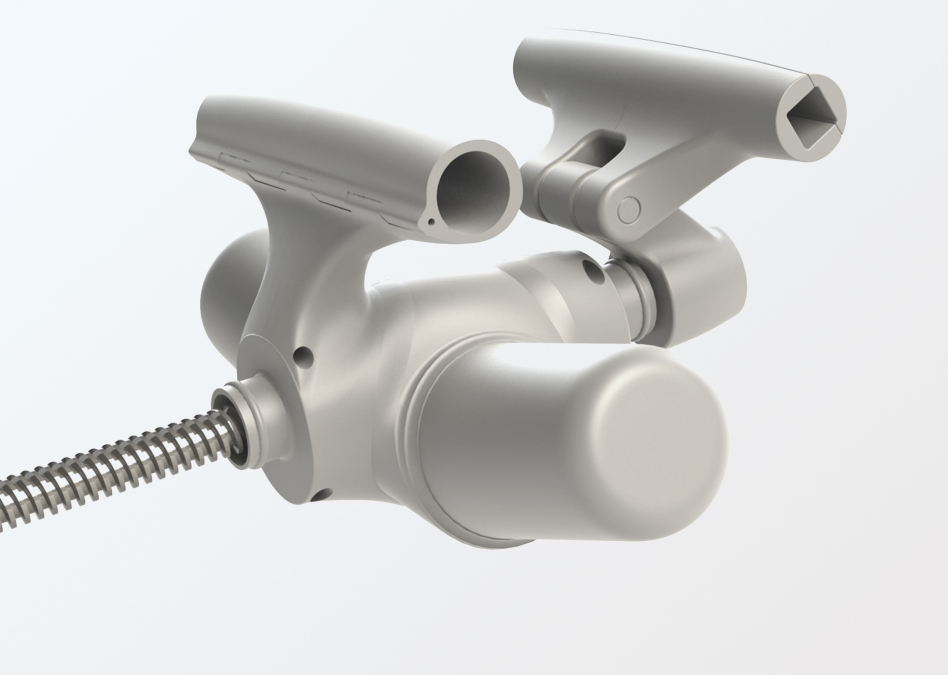

Apex Drive

A power house for smooth and safe patient lifting.

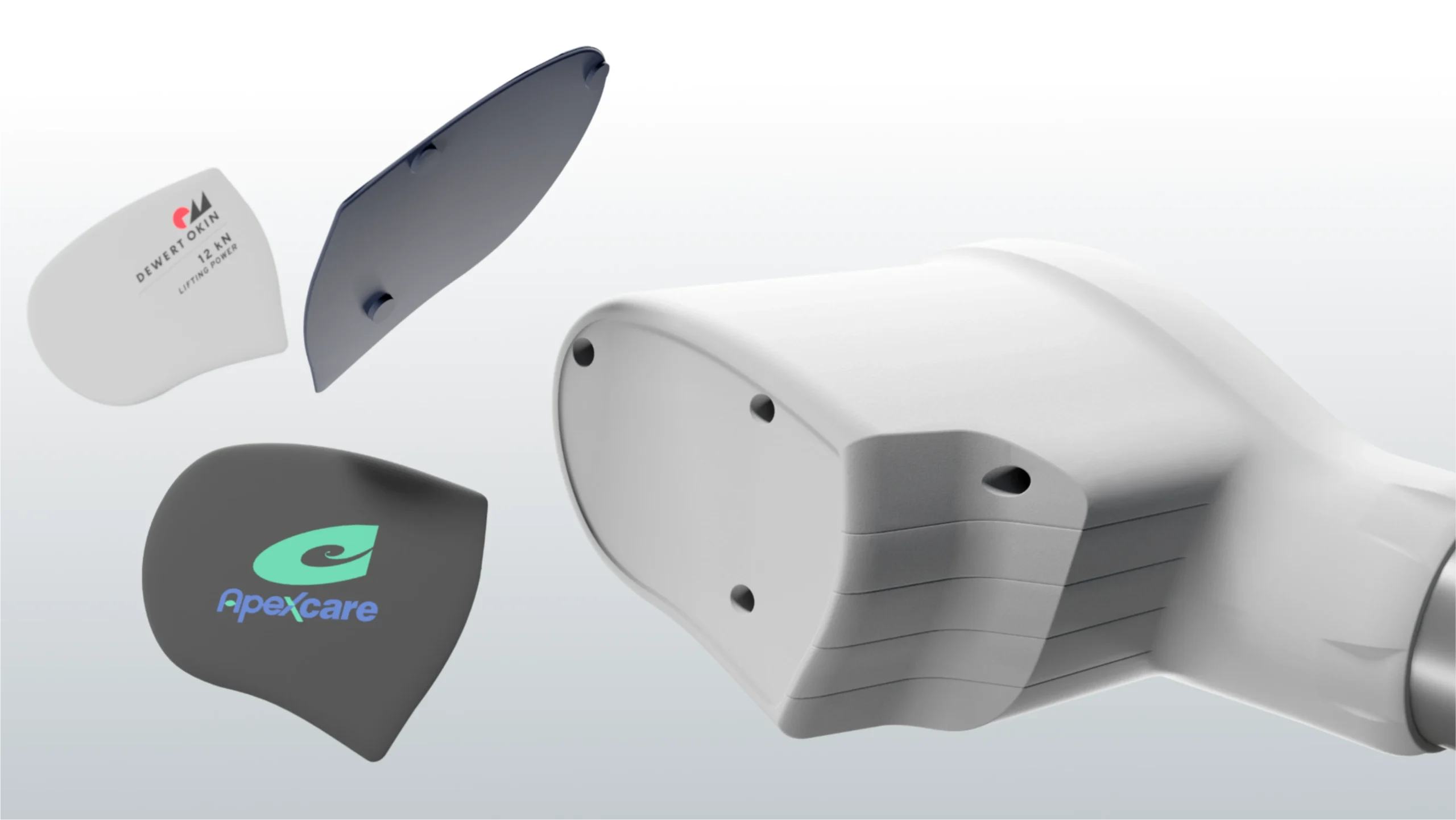

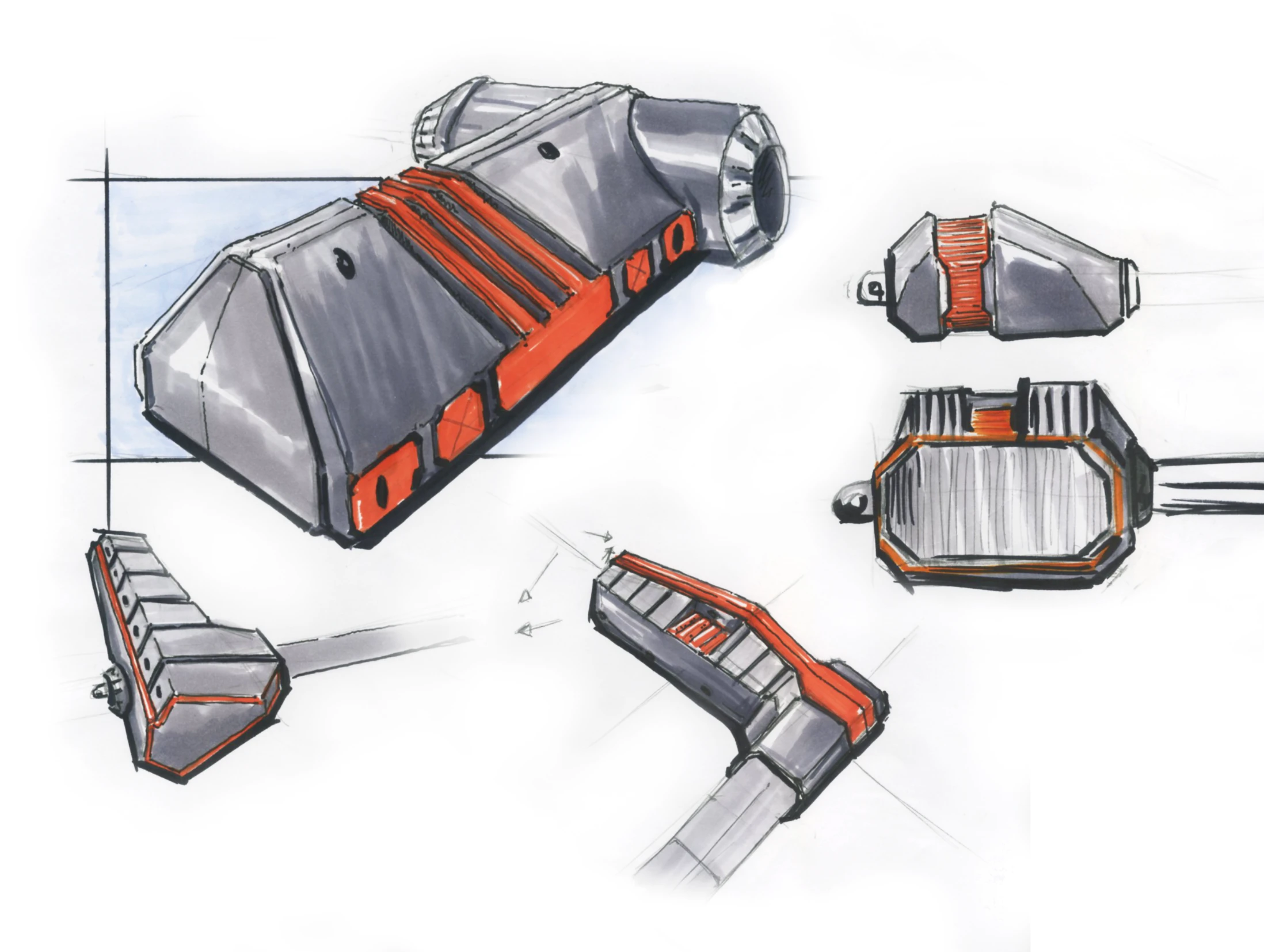

Communicating Power

Visual USP communication

The USP of the specific motor was its ability to extend with up to 12kN of force. To express the power of the linear actuator, we begin with visual research focused on industrial forms that naturally communicate force and performance. We gather references from aviation turbines, V8 engines, cylinder blocks, reinforced housings, heatsinks and high tolerance mechanical assemblies. The goal is to identify visual cues that signal strength. This research guides the aesthetic direction and establishes a design language.

Setting a visual direction

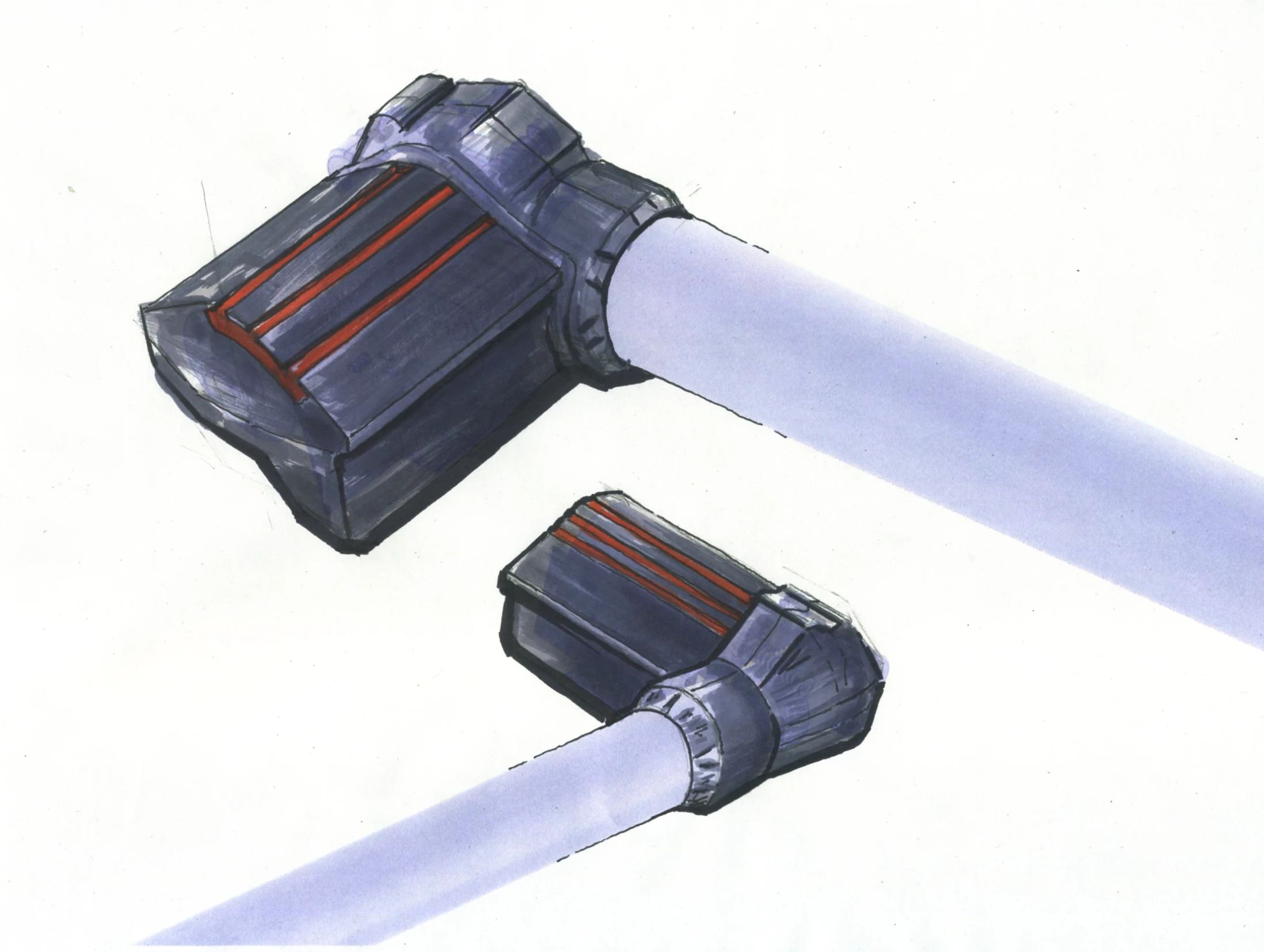

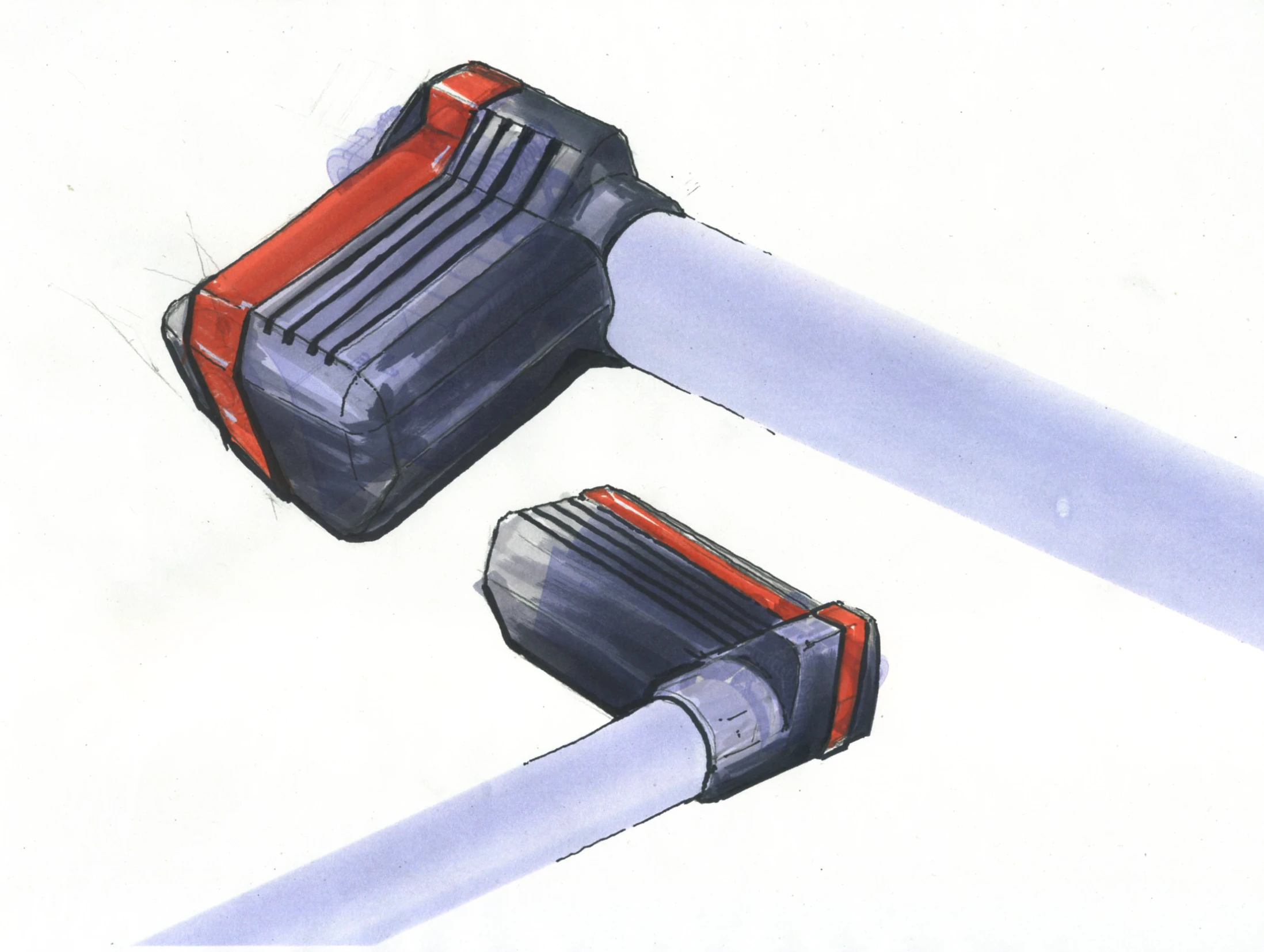

Using these references, we translate the collected visual cues into early concept sketches. This stage is about exploring silhouettes, proportions and recognisable visual markers that subconsciously connect the actuator to the predefined aspects.

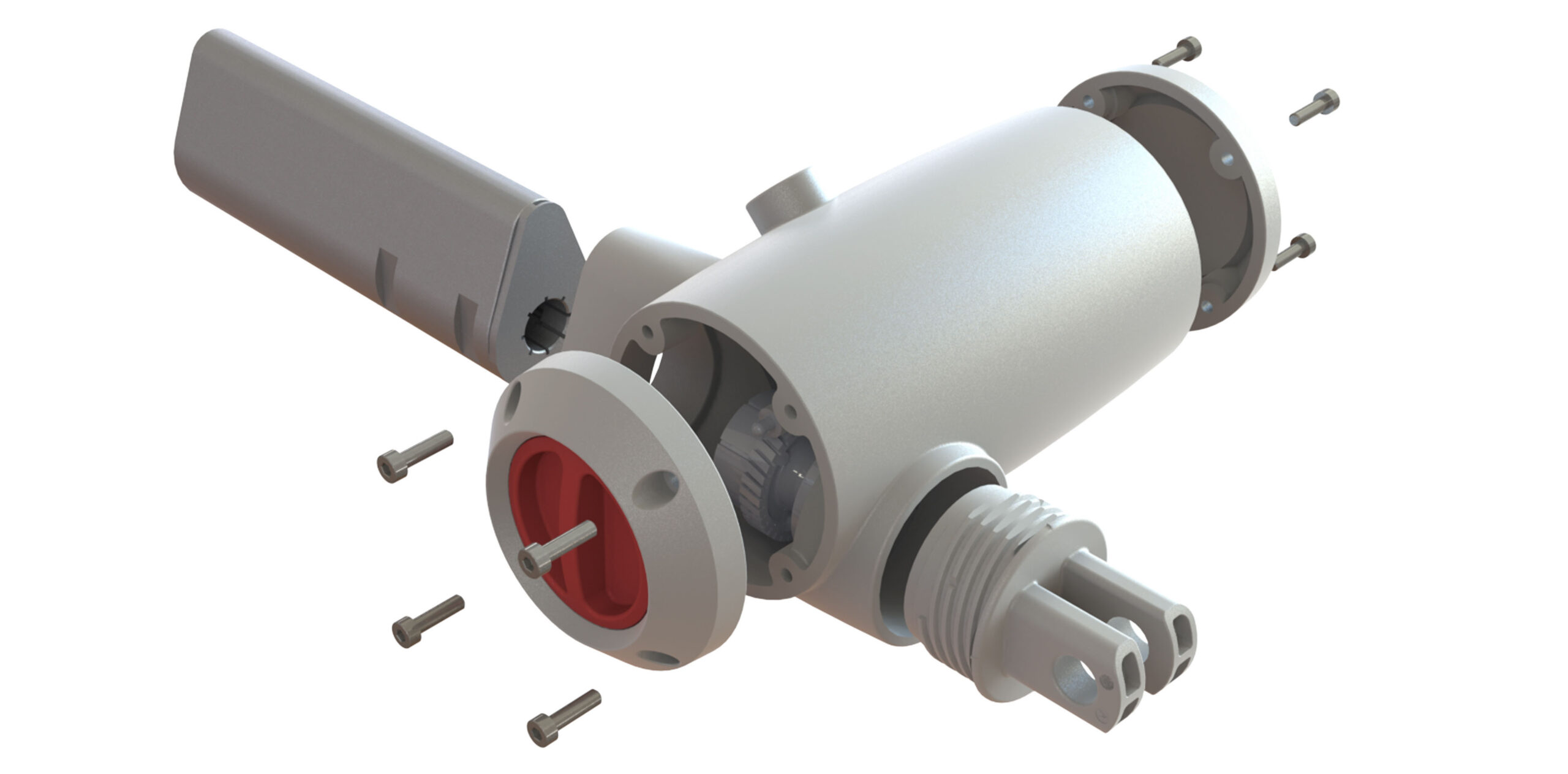

3D Modelling for manufacture

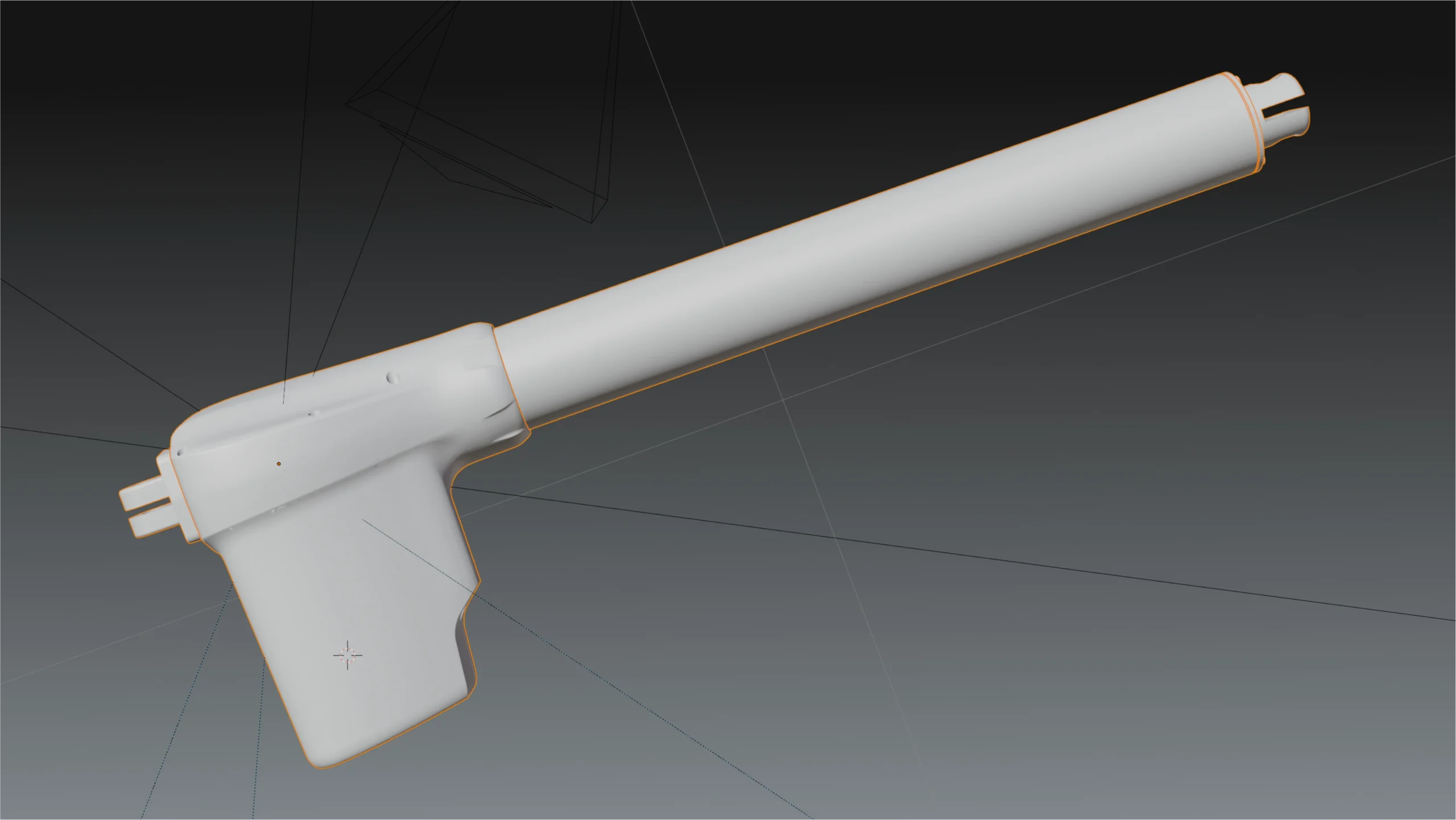

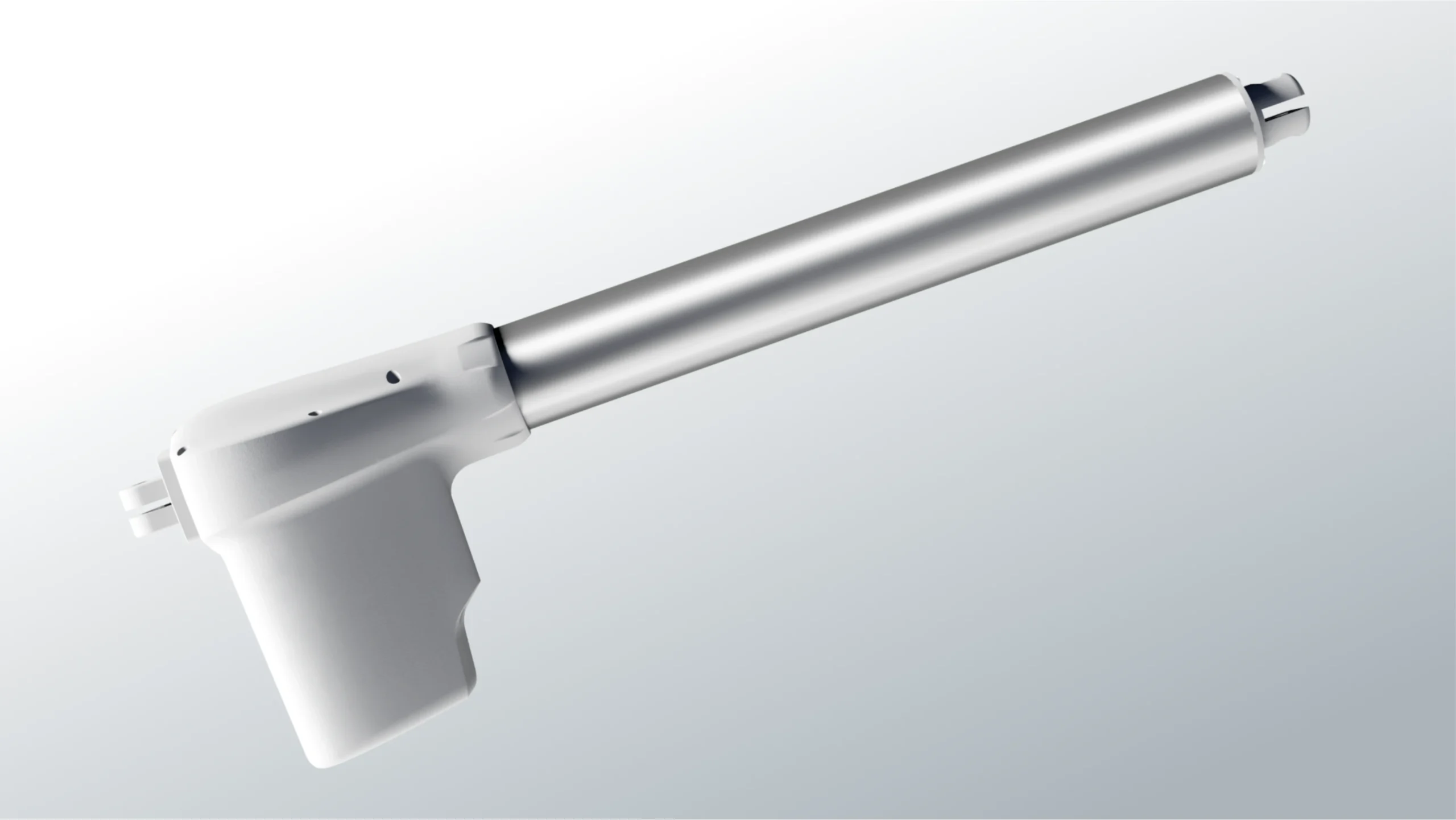

We move into CAD, refining the concept into a form that fits the internal components and engineering constraints. Mounting points, wall thicknesses, tolerances and the motor’s internal geometry re-define the form and the design is shaped into a manufacturable housing while preserving the visual identity from the sketches.

The CAD models are then prepared for the customer and used to produce clean, high fidelity 3D renderings that showcase the final design with realistic materials, lighting, and proportions. In the case of the 12kN Alpha Drive, the design was further refined to suit specific application in a patient lifter.